Understand Core Parameters and Practical Logic in 5 Minutes

Power management ICs (PMICs) are often underestimated in electronic product design. Yet, they play a critical role in ensuring system stability, energy efficiency, thermal control, and even the overall product lifecycle.

Whether you’re a procurement specialist, engineer, or project manager, this article will help you quickly understand how to select the right power chip and make sound technical and commercial decisions.

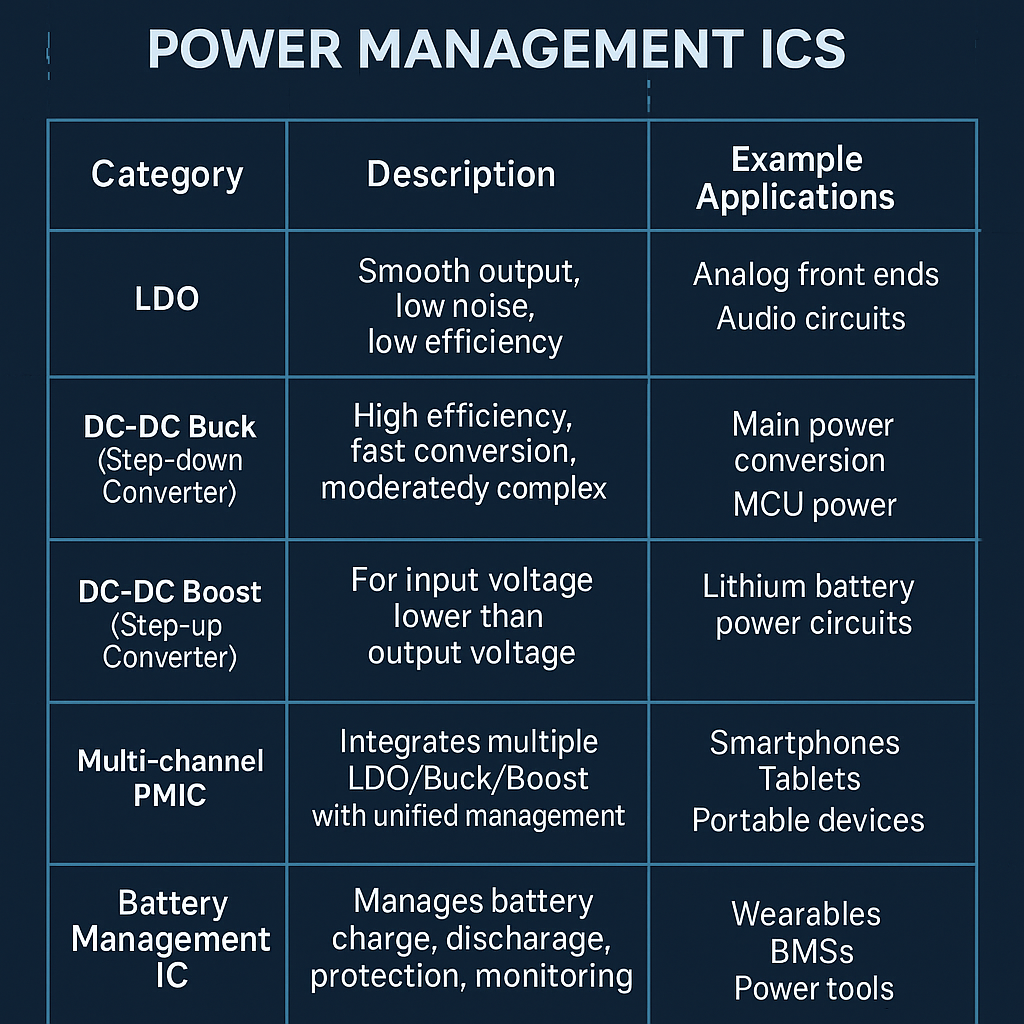

🔋 Understanding the Main Categories of Power Chips

Before diving into selection, it’s essential to understand the common types of power management ICs:

- LDOs (Low Dropout Regulators): Provide stable, low-noise output; simple but inefficient—ideal for analog and audio systems.

- DC-DC Buck Converters: Efficiently convert higher input voltages to lower output voltages; suitable for main power regulation.

- DC-DC Boost Converters: Used when output voltage needs to be higher than input; often seen in battery-powered devices.

- Buck-Boost Converters: Handle input voltages that fluctuate above and below the output; useful for single-cell battery applications.

- Multi-Channel PMICs: Integrate multiple regulators in one chip, optimized for portable electronics and system-on-chip solutions.

- Battery Management ICs: Control charging, discharging, protection, and monitoring for rechargeable battery systems.

📌 Five Key Factors for Choosing a Power Chip

1. Input/Output Voltage Range

Make sure the input voltage covers all expected variations from your power source, and that the output voltage matches the downstream load requirements.

2. Output Current Capability

Ensure the device can deliver peak current loads with a safety margin (usually 10–20%). Don’t forget that package type affects thermal dissipation and real-world performance.

3. Power Conversion Efficiency

In battery-powered systems, every percent matters. Buck converters usually offer 80–95% efficiency, while LDOs are less efficient but simpler and quieter.

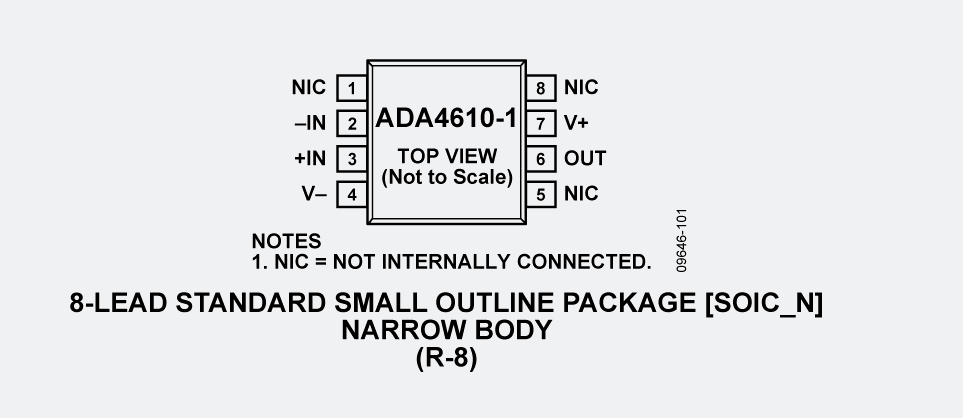

4. Package Type

The choice of package affects size, thermal performance, and layout flexibility. For example, SOT-23 and TSOT are common for small systems, while QFN or BGA are suited for high-performance designs.

5. Switching Frequency

Higher switching frequencies allow for smaller external components but can cause EMI issues. Lower frequencies are more stable but require larger inductors and capacitors.

🧭 What Else Should You Consider?

Beyond the basics, successful power chip selection requires consideration of real-world features:

- Synchronous vs. Asynchronous Topology: Synchronous converters have higher efficiency and fewer external components, but cost slightly more.

- Soft Start & Protection Features: Look for undervoltage lockout (UVLO), overvoltage protection (OVP), thermal shutdown, and short circuit protection.

- Power Sequencing: Some systems (e.g., SoCs) require precise startup sequences for different voltage rails. Ensure the chip supports enable pins or integrated sequencing.

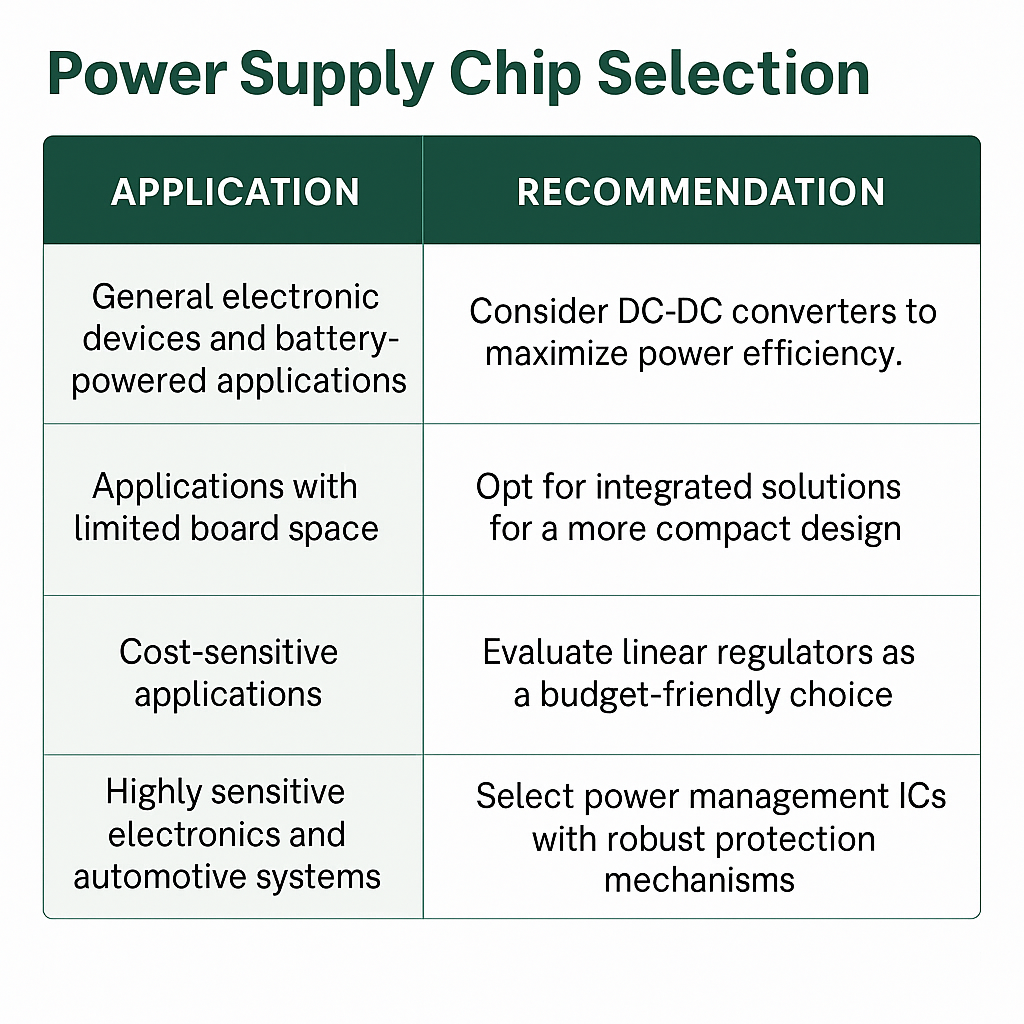

🧠 Application-Based Selection Tips

Selecting the right power IC isn’t just about specs—context matters. Here’s how to approach selection based on usage scenarios:

- For battery-powered systems, focus on low quiescent current and wide input voltage range.

- For mainboard power rails, prioritize thermal performance, integration level, and output accuracy.

- In industrial applications, ruggedness and wide temperature range (-40°C to 85°C) are essential.

- For automotive designs, components must meet automotive-grade standards (e.g., AEC-Q100) and tolerate electrical noise and extreme conditions.

🧾 Final Thoughts

Power chips are not just “supporting roles”—they’re foundational to system integrity and reliability. Choosing the right one is not only about datasheet specs, but also about understanding the application, managing thermal and EMC design, and ensuring long-term availability.

Remember:

💡 A well-selected PMIC can reduce development time, enhance performance, and improve system cost-efficiency.

Need help evaluating your BOM or sourcing the best-fit PMICs? Our team is ready to support your success.

💼 About Us | Singapore Trans Sen Electronics Pte. Ltd.

Founded in 2015, Singapore Trans Sen Electronics Pte. Ltd. is led by a core team of professionals who previously served in world-renowned brands and distributors. With 20+ years of industry experience, our sales, sourcing, and FAE teams work closely to deliver reliable and efficient services to our valued clients.

We specialize in the distribution of electronic components and franchised brands, backed by strong global sourcing capabilities and professional technical support.

🔧 Our Services

- Comprehensive BOM analysis and sourcing

- Obsolete & EOL (End-of-Life) part solutions

- Alternative and cross-reference part recommendations

- Strategic sourcing for long lead-time components

- Global logistics coordination

- In-house technical support and customized FAE consulting

- Buffer stock planning & inventory management

- Support for NPI (New Product Introduction) and mass production

Need help selecting the right components for your project?

Feel free to contact us anytime — we’re here to support your success.