In the semiconductor industry, chip packaging technology not only determines the reliability and size of a chip but also directly affects its thermal performance. As electronic devices become more powerful, increasing power consumption generates more heat, making thermal management a critical challenge in packaging design. This article explores how chip packaging technology influences thermal performance and highlights key heat dissipation optimization strategies.

1. The Relationship Between Chip Packaging and Thermal Performance

When a chip operates, it generates significant heat. Without efficient dissipation, excessive heat can lead to performance degradation, accelerated aging, and even failure. Packaging serves as a bridge between the chip and the external environment, playing a crucial role in how heat is transferred and dissipated. Key factors influencing thermal performance include packaging materials, structural design, and packaging type.

The primary heat transfer paths include:

- From the chip’s internal circuits to the packaging material (chip-to-package interface)

- From the packaging material to the heat sink or PCB (package-to-external environment)

Optimized packaging technology improves thermal conductivity and reduces thermal resistance, leading to better heat dissipation.

2. Major Packaging Technologies Affecting Thermal Dissipation

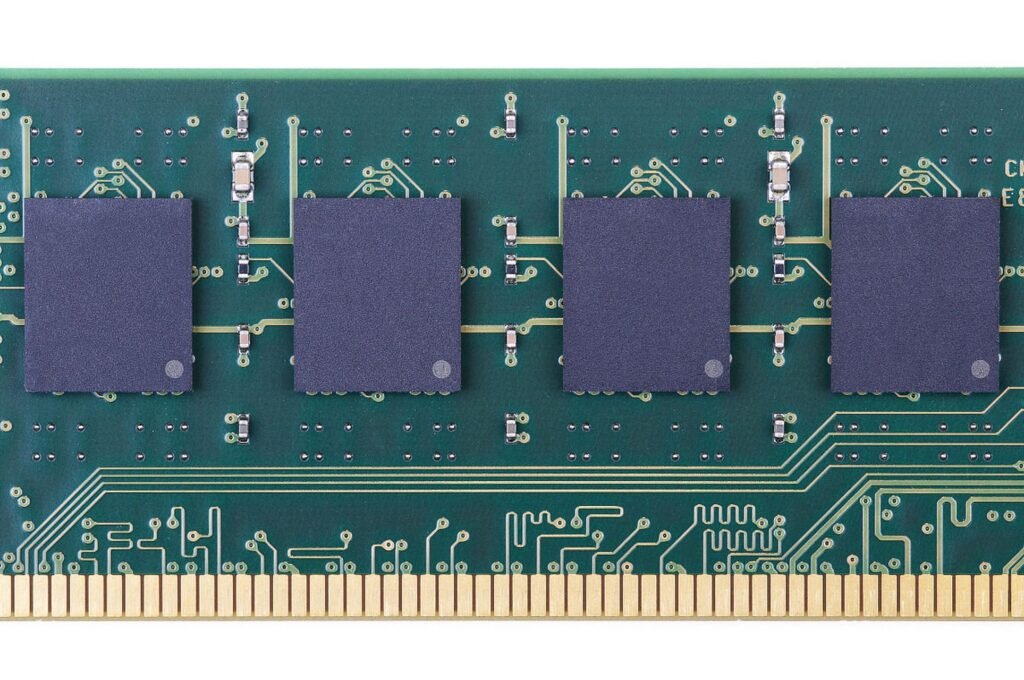

(1) Chip-on-Board (COB) Packaging

COB technology involves mounting the chip directly onto the PCB using thermal adhesives or conductive materials for heat transfer.

- Advantages: Reduces packaging layers, lowers thermal resistance, and enhances heat dissipation efficiency.

- Disadvantages: Requires high manufacturing precision and has reliability concerns.

(2) Ball Grid Array (BGA) Packaging

BGA packaging uses solder balls on the bottom of the chip to connect to the PCB, providing an effective heat dissipation path.

- Advantages: Excellent thermal conductivity, suitable for high-power chips.

- Disadvantages: Sensitive to soldering quality, relatively high production cost.

(3) Flip-Chip Packaging

Flip-Chip technology places the chip upside-down, allowing direct contact between the heat-generating surface and the heat dissipation layer.

- Advantages: Low thermal resistance, short heat dissipation path, ideal for high-performance processors and GPUs.

- Disadvantages: Higher packaging costs and complex manufacturing process.

(4) 3D IC Packaging

3D packaging stacks multiple chips vertically using Through-Silicon Vias (TSVs) for interconnection.

- Advantages: Higher computing density and optimized heat dissipation paths.

- Disadvantages: Complex thermal management requiring advanced cooling solutions like liquid cooling or phase-change materials.

3. Key Technologies for Improving Thermal Performance in Chip Packaging

To optimize thermal performance, the industry has adopted several advanced technologies, including:

✅ High Thermal Conductivity Materials

- Utilizing materials like copper, boron nitride, and carbon nanotubes to enhance heat transfer efficiency.

✅ Optimized Packaging Structures

- Incorporating metal heat sinks, heat pipes, and vapor chambers (VCs) to improve heat dissipation from the chip surface.

✅ Active Cooling Solutions

- Integrating air cooling and liquid cooling technologies for enhanced thermal management.

✅ Low-Thermal-Resistance Soldering

- Using lead-free soldering and nano-soldering materials to minimize thermal resistance at the connection points.

4. Future Trends: Advanced Packaging + Intelligent Thermal Management

As chip power consumption increases, packaging technology is evolving toward more efficient and intelligent thermal management solutions. Emerging trends include:

- Chiplet Packaging: Combining multiple small chips in a single package to optimize power consumption and heat dissipation.

- Integrated Phase-Change Cooling Materials: Automatically adjusting temperature to enhance heat dissipation.

- AI-Driven Thermal Management: Using temperature sensors and real-time cooling control systems for dynamic heat optimization.

In the future, the integration of advanced packaging and intelligent cooling strategies will continue to drive semiconductor performance improvements while ensuring high-power chips operate reliably under demanding conditions.

Conclusion

Chip packaging technology plays a crucial role in determining thermal performance, and different packaging solutions directly impact heat dissipation efficiency and reliability. In high-performance computing, 5G, and AI applications, the combination of advanced packaging and intelligent thermal management will be a key factor in semiconductor industry growth.

For electronic component trading companies, understanding packaging technology trends can help in better evaluating product performance, optimizing supply chain management, and offering more efficient solutions to customers.

📢 Follow us for the latest semiconductor industry insights!