In embedded product design, the MCU (Microcontroller Unit) is one of the most critical components, and its selection directly determines the success or failure of the project. Choosing the right MCU not only meets system requirements but also provides advantages in cost, power consumption, and development time. This article summarizes key experiences in MCU selection from five perspectives to help engineers make informed decisions when designing new products.

I. Analyze the System’s Required Operating Speed

The MCU’s operating speed directly impacts system real-time performance and responsiveness. When selecting an MCU, it’s essential to consider task complexity, real-time requirements, and peripheral processing speed.

1.Clock Frequency Selection: The clock frequency determines the MCU’s processing capability. For simple control tasks, low-frequency MCUs (such as 8-bit or 16-bit) may suffice. For complex algorithms, multitasking, or high real-time requirements, a high-frequency 32-bit MCU (such as ARM Cortex-M series) is recommended.

2.Real-Time Requirements: If the system demands strict real-time performance (e.g., motor control, communication protocol handling), focus on interrupt response time, DMA (Direct Memory Access) support, and the availability of hardware accelerators such as FPU (Floating Point Unit) or CRC (Cyclic Redundancy Check).

3.Multitasking: For systems requiring multitasking, select MCUs that support RTOS (Real-Time Operating System) and ensure sufficient clock speed and memory to handle task scheduling efficiently.

II. Analyze Required Memory Resources

MCU memory resources mainly include Flash (program storage) and RAM (data storage). Proper estimation based on system functionality is essential during selection.

1.Flash Memory: Flash stores program code and constant data. Estimate Flash size based on system complexity, algorithm size, and whether firmware upgrades will be stored. It is recommended to reserve an extra 20%-30% for future expansions.

2.RAM Memory: RAM holds runtime variables, stacks, and dynamic memory. Estimate RAM needs based on the number of tasks, buffer size, and real-time demands, with additional headroom to avoid runtime memory shortages.

3.EEPROM or External Storage: If non-volatile data storage is needed (e.g., user settings, calibration data), check whether the MCU integrates EEPROM or if external Flash/EEPROM components are necessary.

III. Analyze Peripheral and I/O Requirements

Peripheral availability is a key factor when selecting an MCU. Analyze required peripheral types and quantities to ensure the MCU fully supports system functions.

1.GPIO (General Purpose Input/Output): Estimate the number of GPIOs required for buttons, LEDs, sensors, etc.

2.Communication Interfaces: Choose MCUs based on communication needs:

• UART: For serial communication and debugging.

• I2C/SPI: For interfacing with sensors and memory.

• CAN: For automotive and industrial applications.

• USB: If PC or USB device communication is required.

• Ethernet: For network-connected systems.

• Analog Peripherals: Systems requiring analog signal processing should select MCUs with ADCs (Analog-to-Digital Converters), DACs (Digital-to-Analog Converters), and comparators, with appropriate resolution and sampling rates.

3.Timers/PWM: Essential for time measurement, scheduling, motor control, and LED dimming. Ensure sufficient quantity and precision.

IV. Analyze Power Supply and Power Consumption Requirements

Power supply considerations and energy efficiency greatly affect system design, especially for battery-operated products.

1.Operating Voltage: Match the MCU’s voltage requirements (commonly 3.3V or 5V; some support 1.8V or wide voltage ranges) to the system’s power design.

2.Power Consumption: For battery-powered devices, low power consumption is critical. Select low-power MCUs and examine performance in different modes (run, sleep, standby).

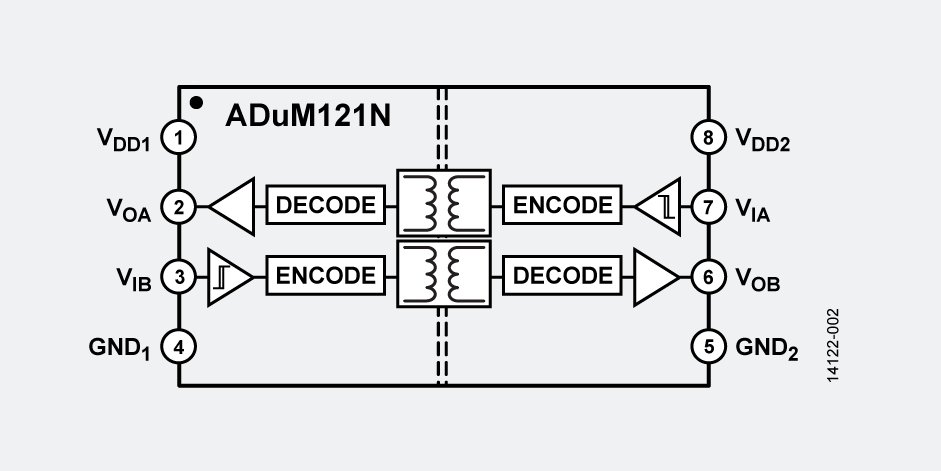

3.Power Management: For complex power schemes (e.g., multi-voltage domains, dynamic voltage scaling), choose MCUs supporting these features or use external power management ICs.

V. Analyze Supply Capability and Cost-Effectiveness of MCU Brands

Supply chain reliability and overall cost-effectiveness must also be evaluated during MCU selection.

1.Brand Selection: Leading MCU brands include STMicroelectronics (ST), NXP, Microchip, Texas Instruments (TI), and Renesas. China brands include Chipsea, Ruimeng, Legendsemi, JoulWatt, Nation, GigaDevice, and HK. Each offers distinct product lines suited to different application needs.

2.Supply Stability: Choose MCUs with stable long-term availability to avoid production disruptions due to shortages or discontinuations.

3.Cost-Effectiveness: Within system requirements, select MCUs that offer the best value by comparing performance, pricing, development tools, and technical support across brands.

4.Development Tools and Ecosystem: A mature ecosystem (IDEs, debuggers, emulators, software libraries) significantly shortens development time. Prefer MCUs backed by rich development resources.

Conclusion

Selecting the right MCU is a critical step in embedded system design. A well-chosen MCU ensures optimal system performance, cost control, and shorter development cycles. By systematically analyzing memory requirements, operating speed, peripheral needs, power considerations, and brand supply capabilities, engineers can comprehensively evaluate options and select the most suitable MCU for their applications.

SINGAPORE TRANS SEN ELECTRONICS PTE. LTD.

Founded in 2015, Singapore Trans Sen Electronics Pte. Ltd. is led by a core team of professionals who previously served in world-renowned brands and distributors. With 20+ years of industry experience, our sales, sourcing, and FAE teams work closely to deliver reliable and efficient services to our valued clients.

We specialize in the distribution of electronic components and franchised brands, backed by strong global sourcing capabilities and professional technical support.

Our Services

• Comprehensive BOM analysis and sourcing

• Obsolete & EOL (End-of-Life) part solutions

• Alternative and cross-reference part recommendations

• Strategic sourcing for long lead-time components

• Global logistics coordination

• In-house technical support and customized FAE consulting

• Buffer stock planning & inventory management

• Support for NPI (New Product Introduction) and mass production

Need help selecting the right components for your project? Feel free to contact us anytime — we’re here to support your success.

You’re welcome to visit our LinkedIn page here.